Precision and Mechanical Engineering Works and Fabrication: Steel’s Role in Gulf Growth

Introduction: Precision Engineering and Sustainable Growth in the Gulf

The Gulf region is undergoing a remarkable transformation, with booming infrastructure projects and increased demand for high-quality building materials. As construction practices evolve, the focus has shifted toward sustainability and precision. At the heart of this transformation is the role of mild and stainless steel suppliers who provide essential materials for precision engineering and fabrication.

Precision engineering plays a crucial role in ensuring the accuracy and efficiency of construction projects, especially in the Gulf, where large-scale infrastructure developments demand top-notch materials. With the emphasis on sustainable growth, particularly in mechanical and precision engineering works, the construction landscape is rapidly transforming.

The Importance of Precision in Mechanical Engineering for Sustainable Projects

In the realm of mechanical engineering works and fabrication, precision is key to reducing waste and optimizing resources. Precision engineering allows for more accurate measurements and designs, leading to efficient material usage and reduced energy consumption during construction. This is especially important for sustainable projects, where minimizing waste and improving resource efficiency are paramount.

Precise steel fabrication, provided by steel and metal product suppliers, enhances the durability and overall performance of construction projects. Steel’s inherent strength, coupled with its ability to be molded with high precision, makes it an ideal material for sustainable construction projects in the Gulf. By using precise engineering methods, contractors can avoid costly delays, reworks, and excessive material usage, aligning with the Gulf’s sustainability goals.

Why Steel is the Backbone of Mechanical Engineering and Fabrication

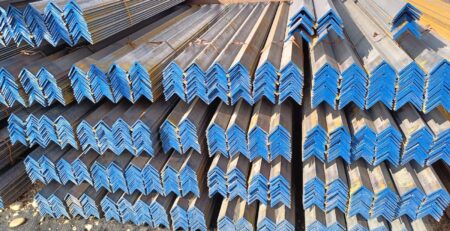

Mild and stainless steel have long been the backbone of mechanical engineering and fabrication. Steel offers unique properties—such as strength, flexibility, and corrosion resistance—that make it indispensable in various industries, including construction, oil and gas, and manufacturing. Its ability to withstand extreme temperatures and harsh environments makes it ideal for the Gulf region, known for its challenging weather conditions.

In precision fabrication, steel’s strength ensures that components can be manufactured to exact specifications without compromising quality. This is crucial in mechanical engineering works, where even the smallest deviation can lead to significant inefficiencies or safety issues. High-quality steel helps to ensure that fabricated components last longer, reduce maintenance costs, and improve the overall sustainability of the construction project. Steel’s durability, combined with its recyclability, aligns with the growing emphasis on environmental sustainability in Gulf projects.

The Role of Quality Steel Suppliers in Precision Fabrication

The role of quality steel suppliers in precision fabrication cannot be overstated. Suppliers of steel and metal products in the Gulf ensure that their materials meet stringent standards of quality and precision, enabling contractors to complete projects efficiently. From sourcing high-grade materials to applying cutting-edge manufacturing techniques, these suppliers are pivotal in delivering steel that fits the exact requirements of a project.

High-quality steel supplied for precision fabrication directly contributes to a reduced carbon footprint. Quality steel minimizes the need for repairs, replacements, and waste, reducing the environmental impact of a project. By working with reputable mild and stainless steel suppliers, contractors can achieve higher levels of precision, sustainability, and cost-effectiveness.

Furthermore, quality steel suppliers in the Gulf not only provide materials but also offer logistical support, ensuring that projects remain on schedule. Timely delivery of precision-engineered steel is critical, as delays can result in increased costs and missed project deadlines. Suppliers with expertise in handling large-scale projects in the Gulf’s fast-paced market are well-positioned to support the region’s expanding infrastructure.

Choosing the Right Steel Supplier for Precision Projects in the Gulf

Selecting the right steel supplier for precision projects in the Gulf requires careful consideration. The Gulf’s demanding environment and large-scale developments necessitate materials that are reliable and durable. When choosing a supplier, contractors must evaluate several key factors:

- Reputation and Certifications: A reliable supplier will have a proven track record of providing high-quality materials. Look for certifications that attest to their compliance with industry standards.

- Material Quality: Whether it’s mild steel, stainless steel, or specialty metal products, the supplier should offer materials that meet project-specific needs.

- Logistical Expertise: Timely delivery and logistical efficiency are critical in large-scale projects. Suppliers with regional experience in the Gulf are better equipped to handle the challenges posed by large infrastructure developments.

- Sustainability Practices: As sustainability becomes more important, consider suppliers who prioritize green practices, such as reducing waste during production and offering recyclable materials.

By choosing the right supplier, contractors can ensure that the steel and metal products used in their precision and fabrication projects meet both quality and sustainability standards.

The Future of Precision Engineering and Fabrication in Sustainable Construction

Looking ahead, the future of precision engineering and fabrication in the Gulf will be driven by advancements in steel technology and a heightened focus on sustainability. As the demand for greener construction practices grows, steel suppliers will continue to innovate by offering materials that support sustainable development goals. This includes the use of advanced manufacturing techniques that reduce waste, energy consumption, and the overall environmental impact of the fabrication process.

The rise of automation and digital technologies, such as AI and 3D printing, is also set to revolutionize precision fabrication. These technologies enable greater accuracy, faster production times, and more efficient use of resources. For the Gulf, where infrastructure projects are expansive and complex, these innovations will be essential in achieving precision and sustainability on a larger scale.

Moreover, the use of modular construction, where pre-fabricated steel components are assembled on-site, will grow in popularity. This method minimizes waste, reduces on-site construction time, and leads to more sustainable building practices. With mild and stainless steel suppliers continuing to innovate, the future of fabrication in the Gulf looks set to embrace both precision and sustainability.

Conclusion: The Gulf’s Future Relies on Precision and Quality in Steel Supply

As the Gulf region continues its rapid development, the demand for precision engineering and fabrication will only increase. High-quality steel and metal product suppliers, like Heera Metals, play a crucial role in meeting this demand by providing top-grade materials that adhere to the highest standards for construction projects. Mild and stainless steel are essential for creating durable, sustainable, and precise structures that can withstand the Gulf’s challenging environment.

By partnering with a reliable supplier, contractors can ensure that their projects are not only efficient and cost-effective but also sustainable. Heera Metals‘ commitment to timely delivery and sourcing from trusted vendors guarantees that clients receive high-quality materials, aligning with the region’s growing focus on precision engineering and sustainable development.

Leave a Reply